Product Development &

Product Optimization

During product development and optimization, it is also important to monitor the aroma spectrum of the raw materials and any potential changes during the manufacturing process in order to achieve the desired result in the final product. The decisive factors for the aroma of a processed product are the raw materials and any flavors used, which should be of consistent quality and composition.

However, various manufacturing steps such as heating, drying, roasting, or fermentation, and the resulting chemical reactions, often lead to the formation of desired flavors. At the same time, however, off-flavors can also form, or desired aroma compounds can be degraded from the raw materials.

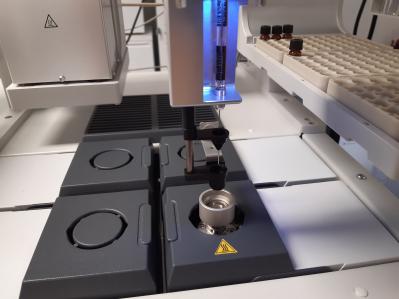

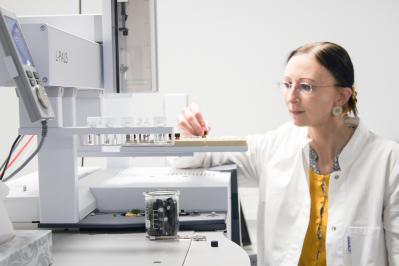

Through qualitative and quantitative analysis of the aroma compounds contained in raw materials, the finished product, and intermediate products, conclusions can be drawn about which factors significantly influence the aroma of the final product and how this can be optimized. aromaLAB offers the full range of modern analytical and instrumental techniques combined with individual, customer-oriented consulting.